On the most basic level, human beings are made up of five major components:

-

- A body structure

-

- A muscle system to move the body structure

-

- A sensory system that receives information about the body and the surrounding environment

-

- A power source to activate the muscles and sensors

-

- A brain system that processes sensory information and tells the muscles what to do

Of course, we also have some intangible attributes, such as intelligence and morality, but on the sheer physical level, the list above covers it.

A robot is made up of the very same components. A basic typical robot has a movable physical structure, a motor of some sort, a sensor system, a power supply, and a computer “brain” that controls all of these elements. Essentially, robots are human-made versions of animal life — they are machines that replicate human and animal behavior. Many people define a robot as anything that they recognize as a robot. Most roboticists (people who build robots) use a more precise definition. They specify that robots have a reprogrammable brain (a computer) that moves a body. Robots are distinct from other movable machines such as tractor-trailer trucks because of their computer elements. Even considering sophisticated onboard electronics, the driver controls most elements directly by way of various mechanical devices. Robots are distinct from ordinary computers in their physical nature — normal computers don’t have physical bodies attached to them.

How do industrial robots work?

These collaborative tools are programmable and multifunctional, and one of the most important components is the controller. It is the brain of the robot and is where its movements are controlled, through the computer system that will program the instructions of the tasks to be performed.

And to provide them with the precision of movements, they have installed a series of sensors that allow them to control both the space to move in a specific way, as well as pressure sensors, to perform the work of maximum precision.

And all this is done thanks to robotics programming and the development of computer languages applied to this discipline, such as C/C++, which has resulted in a very broad field of robotic software.

The aim is that these machines can do all kinds of tasks in the industrial sector, such as drilling and cutting, which requires great precision and speed, this type of cutting can be done with a laser to cut thick materials without wearing out the blade, they can also weld and melt, pack and palletize, handle and transport goods in warehouses, and even monitor the quality of processes.

Although the most commonly used manufacturing robot is the robotic arm, controlled by a computer (controller), these can be adapted according to the type of activity they are going to perform, thanks to the part called end effector, or end-of-arm tool, i.e. the tool that executes the activity, and which varies according to the task for the specific task to be performed.

The most common robots in the industry are manipulators. They are characterized by having a structure in the form of an articulated arm (SCARA) with up to 6 axes or joints, which gives them great mobility to perform tasks such as assembling and welding parts, painting, packaging, and palletizing, among many others. In addition, they can be Cartesian, if they move in the 3 axes (X, Y, Z) or if they have wheels to move in different directions they are considered mobile robots. The latter is very useful for transporting materials or products both in the production sector and in the logistics sector.

Understanding the Mechanics Behind Robotics

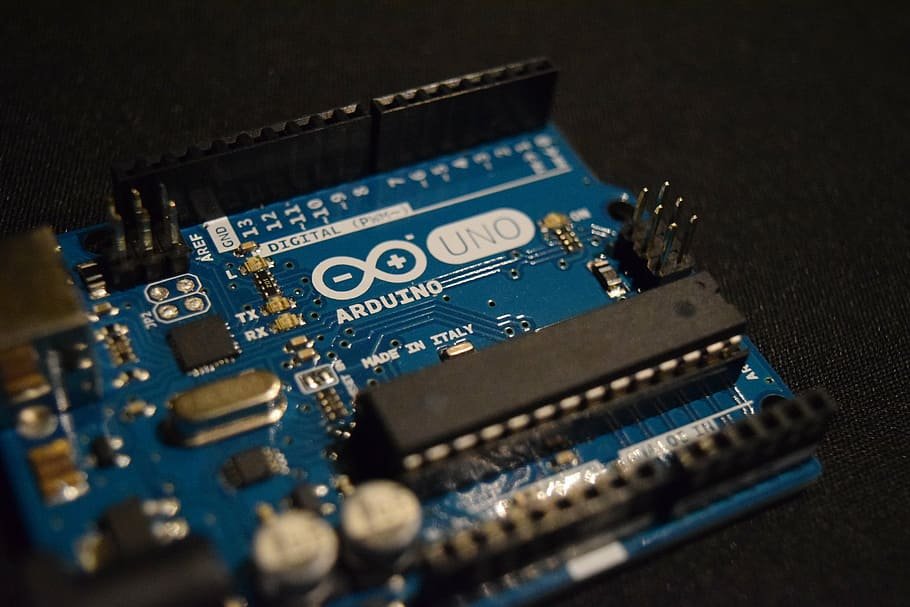

You can think of the robot as a machine with a computer application operating it. The components of the robot form two large groups: hardware and software.

Hardware

A robot’s hardware includes the body, motors, and sensors.

The body shape depends on the type of robot or the application field. Some examples of a robot’s body include humanoid robots, arms-only, legs-only robots, and wheeled robots. The body is mostly covered by metal, plastic, or some other material (such as carbon fiber) that protects the inside of the robot. An important aspect of the protection is that with every additional gram, the motors and energy consumption must be adjusted.

Motors move the robot and its parts. There are several types of motors that are applied in robotics, including bidirectional step motors, rotational motors, pumps, and vibrating disks. If the robot has a complex body, several motors have to be synchronized. The synchronization of the motors is typically performed on a micro-scale. This means that the control of the motors for particular actions, like taking one step ahead with the left foot or lifting the right arm, is predefined. When the robot is performing complex tasks, a sequence of these predefined tasks is executed in a custom order – thus, the robot goes from A to B, or grabs some object and brings it to the target area.

Sensors are used to collect data about the environment, which can then be processed by the computer so it can understand the environment and perform actions accordingly. A wide range of sensors can be built into robots, including cameras, microphones, pressure sensors, thermometers, humidity meters, position sensors, speed sensors, location sensors, and tactile sensors, to name just a few.

Energy is needed by the robot – without it, the robot cannot move or think, which literally means running algorithms on the computer. The energy source is usually electricity, from the electrical network through wires, from a built-in battery, or from solar power. Sometimes robots are operated by gas. The purpose of the robot usually defines which option is better.

Software

Software controls the robot. Without software, the robot won’t be able to operate. In many cases, the robot’s software has parameters that can be set, for example with a smartphone application or with a dedicated input device, like buttons.

The software can be a built-in “hard-wired” solution that cannot be changed later. Older or simpler robots usually utilize this approach. In more enhanced solutions, the software can be updated or upgraded remotely through the internet. The owner of the robot might not even notice the upgrade. Being able to remotely update or upgrade the software helps the developer of the robot to introduce new functionalities, to improve the service, or to correct possible errors. A third type of software allows minor or major modifications or even makes it possible to develop software from scratch in case of general-purpose robots – as discussed previously.